Die Cut Press Parts

PARTS & SERVICE

Expert parts & service at your fingertips. Our highly trained technicians are ready to visit your site any time maintenance is needed.

Service, Upgrading & Rebuilding:

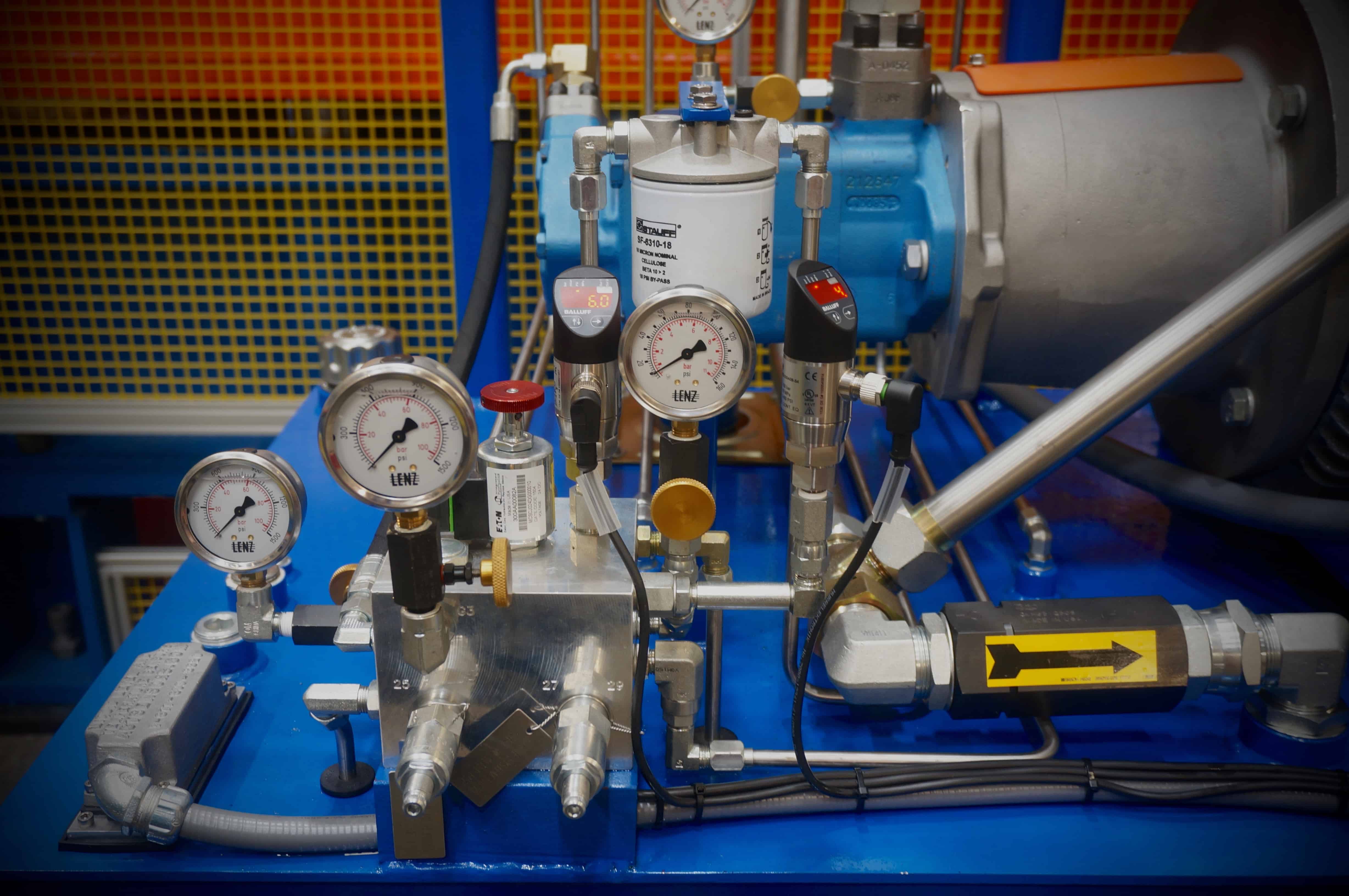

Hydraulic Upgrades:

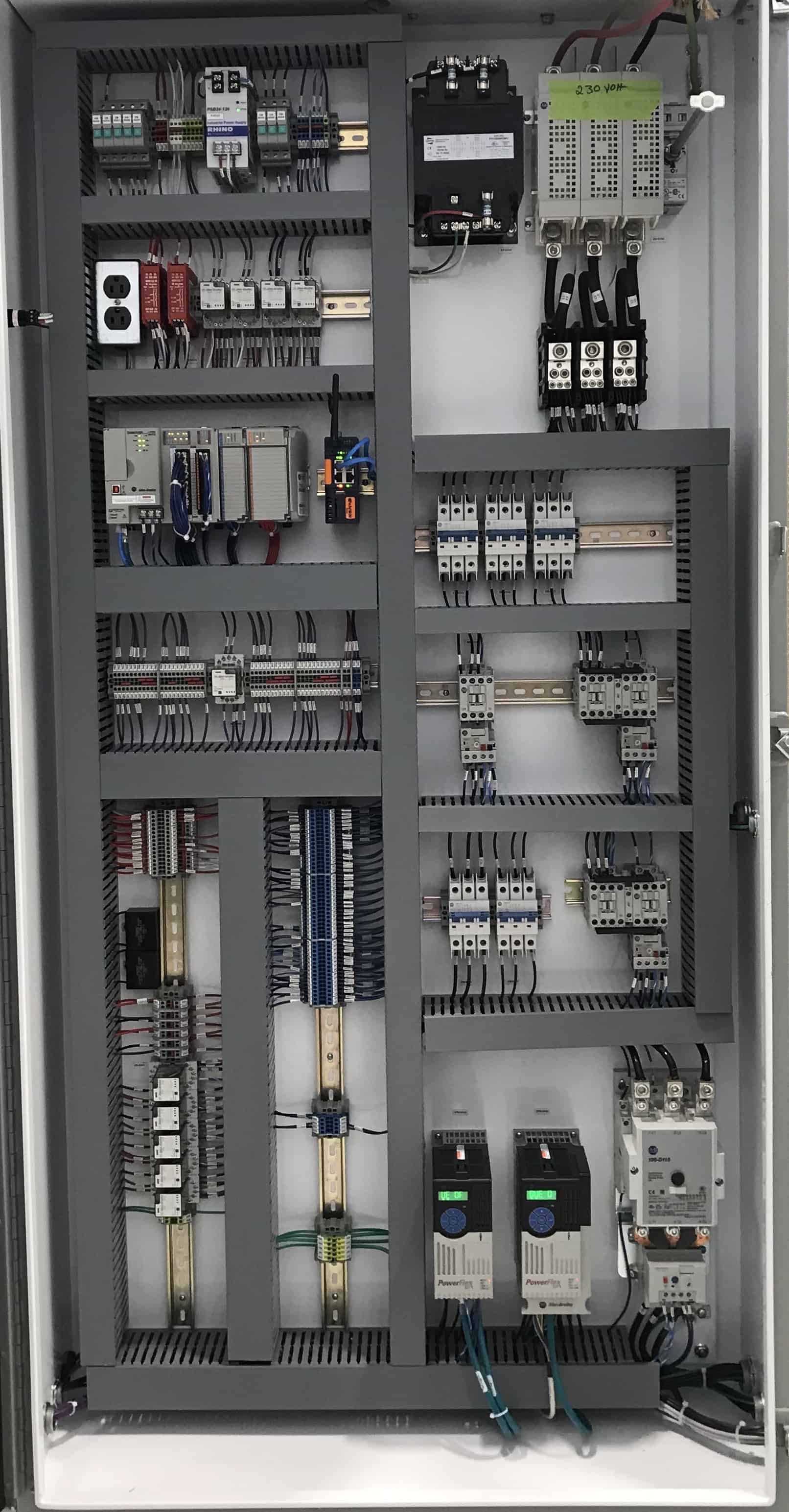

Electrical Upgrades:

Bruno will inspect your electrical system and give you a cost-effective repair to keep your machine from any costly downtime. These upgrades can include the following:

– A new complete Main Panel, with PLC and safety circuit

– A New 10” colored HMI to replace those costly push buttons

Rebuilding:

We will use our professionally trained staff with over 75 years of experience to inspect, report and complete the correct rebuilding process for your machine(s).

– BRUNO presses will be completely disassembled and inspected.

– The Hydraulic System will be completely flushed and cleaned.

– The Electrical System will be completely.

– Guarding will be completely new.

– BRUNO will then re-assemble the machine and do a complete testing of the system before shipping to your plant.